- April 19, 2024

Energy Management for Increased Plant Efficiency

Purchased fuel and electricity consumption are two areas where any improvements in efficiency directly impact a company’s bottom line. Having the ability to monitor the end-use location of fuel throughout a facility as well as the consumption specifics for individual applications — predominately the boiler — can offer insight to potential areas of improvement. A similar statement can be made for electricity consumption: reductions can be realized by simply identifying where the energy is being lost.

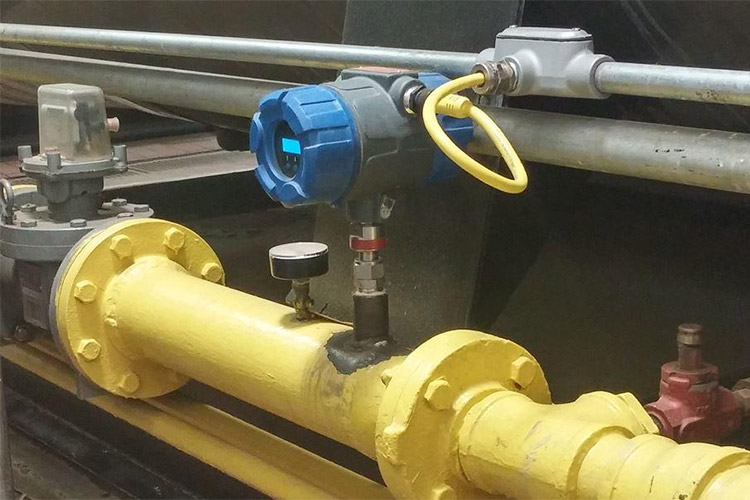

In the energy management arena, the ability to better monitor combustion air, fuel gas flow and compressed air can help identify losses that over short periods of time can affect a plant’s profitability. The two key phrases when discussing instrumentation for the aforementioned are “cost effective” and “return on investment.” Without question, any situation can be resolved if enough financial resources are thrown in its direction. The idea is to realize the benefit in the shortest time frame possible at the most reasonable cost. Thermal dispersion mass flow meters meet these criteria.

Thermal mass flow meters are primarily used in air and gas flow measurement applications. The meters consist of a transmitter and probe with temperature sensors (RTDs) located in the pins at the bottom of the probe. The reference sensor measures the process temperature and the other sensor is heated to a specific temperature above the reference. As the flow rate increases, heat gets taken away from the heated sensor. More power is then applied to the heated sensor to maintain the temperature difference. The relationship between power and mass flow rate is established during factory calibration.

Thermal mass flow meters have many features that are particularly well suited for energy management. Aside from an economical purchase price, they are easy to install and have calibration verification procedures that can be run in the field, providing a low total cost of ownership. They are one of the only technologies that directly measure mass flow without the need for pressure or temperature compensation. A strong signal at low flows / low pressures with a high turndown allow the technology to be utilized all over the plant, including key processes such as combustion air flow, fuel gas flow and compressed air.

For more information on energy management and other steam generation applications, download our steam generation white paper.

White Paper: Hidden Profits in Steam Generation

Download our white paper on steam generation to discover how to optimize the steam generation cycle and condensate recovery process for increased profitability.

DOWNLOAD