- February 12, 2024

Outstanding ROI, Process Monitoring and a 3-Year Warranty on Water Cut Monitor

The Original Case

One of the world’s leading oil companies realized that their water cut instrumentation drifted by up to 20% per year and caused them to allocate 1,400 hours for calibration and false alarms each year. They contacted Drexelbrook to check if the Universal V Water Cut Monitor would be a worthy substitution and ended up investing in more than 100 Drexelbrook Water Cut Monitors due to the positive test results. Was it expensive? No, the customer achieved a ROI in less than 2 years!

Drexelbrook has now decided to underline the reliability of the Universal V Water Cut Monitor by providing a 3-year warranty. In the case above, this exceeded the time frame that the customer spent on switching Their equipment and obtaining a true payback on that investment.

Sampling of Water in Oil vs Continuous Measurement

Collecting samples from the process for external laboratory analysis is common and may be necessary. The working hours spent on collecting samples and the expense for lab tests should be compared to the onetime cost of continuous measurement performed by the Universal V. The precision real-time water-in-oil analysis performed by the Drexelbrook Water Cut Monitor can quickly reduce the need for the detailed and complex lab-tests significantly, and will from that perspective be a significantly cheaper solution.Technological Advantages of Universal V Real-Time Water Cut Monitor

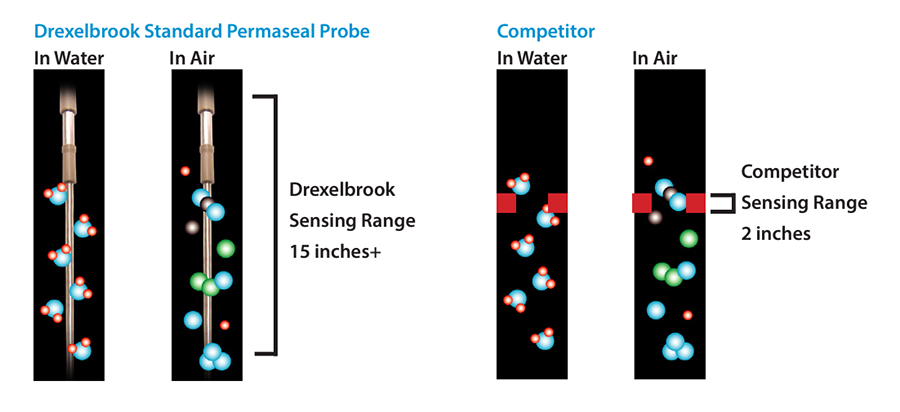

Universal V Water Cut Monitor uses the RF Admittance technology to measure the water content of the media by sensing the difference in the dielectric constants of oil (K=2.3) and water (K=80). The sensing element can exceed 38cm/15” on insertion probes and over 76cm/30” on some inline spool systems. This means that the capacitance measurement will produce a more accurate reading compared to many instruments that only measure on approximately 5cm/2” of the media passing by.

Easy Mounting

Drexelbrook Universal V is designed for various types of mounting, including insertion probes through a welded coupling or pipe elbow and in-line spool style probes. These are very easy to mount without having to remove entire portions of the piping systems. The display housing can be mounted remotely to provide easy access to the real-time measurement display, or the data can be transmitted via HART or 4-20mA to a control room. The probes handle up to 1500 psi and 230°C/450°F.Product Manager Sunny Singh explains:

“Drexelbrook Universal V Water Cut Monitor is based on RF Admittance technology. The RF Admittance technology provides accurate measurements unaffected by paraffine buildup. Some technologies can easily do faulty measurement caused by abrasion due to sand in the fluid or paraffin build-up, Universal IV probes are designed to be easy to clean, ignores coatings and withstands the sandy media. The data from probes are temperature and density compensated, meaning these probes delivers outstanding results even under the harsh conditions you experience in refinery pipes.

The sensing element on Universal V utilizes a PEEK (Poly Ether Ether Keytone) material and stainless-steel sensing rod that is extremely durable and that is why we do not need epoxy coatings. Epoxy coatings are a maintenance burden, they degrade over time, especially when placed in the turbulent process flow. The

degradation of the epoxy coating will result in erratic outputs and requires expensive, reoccurring maintenance by field personnel. This is one of the great hidden expenses in installing instrumentation that are not ideal for the application, and that is one of the areas that makes a cheap solution really expensive.”

Benefits

Universal V Water Cut Monitor is proven to deliver reliable measurements, trustworthy longevity and delivers a fast ROI.

• 3 year warranty

• Various models to fit almost any application

• Ignoring paraffin and other coatings

• 0-50% in light oil, 0-80% in heavy oil

• Easy calibration

• Temperature range: Up to 232°C (450°F)

• Process pressure: Up to 103 bar (1,500 psi) eap solution really expensive.”

Request more information to see how we can help you with a level measurement solution that suits your need.

Drexelbrook Learning Zone

Visit the Drexelbrook Learning Zone today! Discover a wealth of resources, including in-depth videos on our Universal Water Cut Monitor and the cutting-edge Cote-Shield Technology. Equip yourself with the knowledge to make informed decisions for your applications!

LEARNING ZONE