L072 Series

Side-mounted float level switch with manual reset

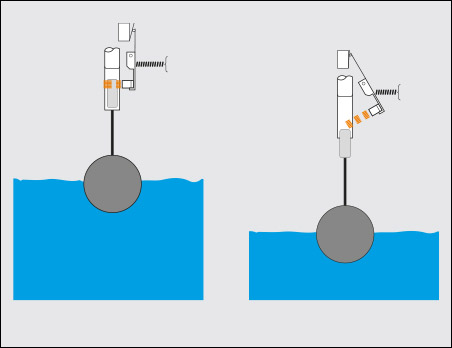

The horizontally-mounted L072 is a rugged, hazardous duty level switch equipped with a “push to test” function for monitoring liquid levels. Its all stainless steel construction and ultra-light float provide reliable performance in numerous media and the ability to sense dissimilar fluid interfaces within a 0.1 differential. The L072 is FM-approved for Class I, Div I, Groups A, B, C, D, E, F & G hazardous locations and can withstand pressures up to 1,000 PSIG. Units can be installed for either normally-open or normally-closed operation.

-

Features

-

Applications

-

Specifications

-

Downloads

- Manual “Push to Test” Function

- Available Up to 1,000 PSIG

- Reliable Reed Switch Action

- UL, FM & CSA Approved

- Operates on Falling or Rising Level

- Interchangeable Normally-Open or Normally-Closed

- Optional Hazardous Area Enclosures & Interface Level Switch Calibration

- Optional On-Board 5 Amp DPDT Relay

- Food & Beverage Equipment

- Food Warmers

- Storage Tanks

- Fuel Dispensing Systems

- Humidity Control Equipment

| L072 | 1 ½" NPT | 316 STAINLESS STEEL | 0.4 | -40º TO +300º F (-40º TO +148.9º C) | 1,000 PSIG (68.9 BAR) | SPST 100 VA | NO/NC |

|---|---|---|---|---|---|---|---|

| L072 | 2" NPT | 316 Stainless Steel | 0.4 | -40º to +300º F (-40º to +148.9º C) | 1,000 PSIG (68.9 bar) | SPST 100 VA | NO/NC |

| L072 w/ Adj. Rod | 2" NPT | 316 Stainless Steel | 0.4 | -40º to +300º F (-40º to +148.9º C) | 1,000 PSIG (68.9 bar) | SPST 100 VA | NO/NC |

| L072 | 2" #150 Flange | 316 Stainless Steel | 0.4 | -40º to +300º F (-40º to +148.9º C) | 175 PSIG (12.1 bar) | SPST 100 VA | NO/NC |

| L072 | 2 ½" #150 Flange | 316 Stainless Steel | 0.4 | -40º to +300º F (-40º to +148.9º C) | 175 PSIG (12.1 bar) | SPST 100 VA | NO/NC |

| L072 | 3" #150 Flange | 316 Stainless Steel | 0.4 | -40º to +300º F (-40º to +148.9º C) | 175 PSIG (12.1 bar) | SPST 100 VA | NO/NC |

| L072 | 2" #300 Flange | 316 Stainless Steel | 0.4 | -40º to +300º F (-40º to +148.9º C) | 455 PSIG (31.4 bar) | SPST 100 VA | NO/NC |

| L072 | 2 ½" #300 Flange | 316 Stainless Steel | 0.4 | -40º to +300º F (-40º to +148.9º C) | 455 PSIG (31.4 bar) | SPST 100 VA | NO/NC |

| L072 | 3" #300 Flange | 316 Stainless Steel | 0.4 | -40º to +300º F (-40º to +148.9º C) | 455 PSIG (31.4 bar) | SPST 100 VA | NO/NC |

| L072 | 1 ½" NPT | 316 Stainless Steel | 0.4 | -40º to +300º F (-40º to +148.9º C) | 1,000 PSIG (68.9 bar) | SPDT 100 VA | NO/NC |

| L072 | 2" NPT | 316 Stainless Steel | 0.4 | -40º to +300º F (-40º to +148.9º C) | 1,000 PSIG (68.9 bar) | SPDT 100 VA | NO/NC |

| L072 | 2" #150 Flange | 316 Stainless Steel | 0.4 | -40º to +300º F (-40º to +148.9º C) | 175 PSIG (12.1 bar) | SPDT 100 VA | NO/NC |

| L072 | 2 ½" #150 Flange | 316 Stainless Steel | 0.4 | -40º to +300º F (-40º to +148.9º C) | 175 PSIG (12.1 bar) | SPDT 100 VA | NO/NC |

| L072 | 3" #150 Flange | 316 Stainless Steel | 0.4 | -40º to +300º F (-40º to +148.9º C) | 175 PSIG (12.1 bar) | SPDT 100 VA | NO/NC |

| L072 | 2" #300 Flange | 316 Stainless Steel | 0.4 | -40º to +300º F (-40º to +148.9º C) | 455 PSIG (31.4 bar) | SPDT 100 VA | NO/NC |

| L072 | 2 ½" #300 Flange | 316 Stainless Steel | 0.4 | -40º to +300º F (-40º to +148.9º C) | 455 PSIG (31.4 bar) | SPDT 100 VA | NO/NC |

| L072 | 3" #300 Flange | 316 Stainless Steel | 0.4 | -40º to +300º F (-40º to +148.9º C) | 455 PSIG (31.4 bar) | SPDT 100 VA | NO/NC |

Accessories

Related Articles

Do you want personal advice for your specific control process?

Contact us directly or reach out to your local AMETEK Level Measurement Solutions representative!

FIND MY LOCAL REPRESENTATIVE