L250AD Series

Integral dispensing tube level switches

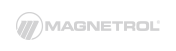

The L250AD is a combination single or dual-point level switch and integral dispensing tube designed for use in the pharmaceutical industry. The unit has the capability of dispensing liquids as well as monitoring their levels of critical laboratory solutions from within a plastic-lined container. Its spring-loaded mount adjusts the sensor for optimum submergence and its ultra low-level float requires only 3/16″ of liquid to operate. Options include the choice of a polysulfone/polypropylene or stainless steel construction with a variety of switch types.

-

Features

-

Electrical

-

Specifications

-

Downloads

- Compact, Requires Minimal Space

- Single & Dual Setpoints

- 1.125″ (28.5 mm) Diameter (Standard)

- Custom Diameters Available

- Spring-Loaded Mount for Self-Adjustment

- FDA & NSF-Approved Plastic Available

- SPST or SPDT Switch Types

- Food & Beverage

- Medical

- Pharmaceutical Packaging

- Low-Level Process Control

| L250AD | POLYPROPYLENE | POLYSULFONE | -40º TO +150º F (-40º TO +65.6º C) | 150 PSIG (10.3 BAR) | 0.93 | SPST 10 VA |

| L250AD | 316 Stainless Steel | 316 Stainless Steel | -40º to +300º F (-40º to +148.9º C) | 150 PSIG (10.3 bar) | 0.93 | SPST 10 VA |

| L250AD | Polypropylene | Polysulfone | -40º to +150º F (-40º to +65.6º C) | 150 PSIG (10.3 bar) | 0.93 | SPDT 3 VA |

| L250AD | 316 Stainless Steel | 316 Stainless Steel | -40º to +300º F (-40º to +148.9º C) | 150 PSIG (10.3 bar) | 0.93 | SPDT 3 VA |

-

Product Catalogs

-

L250AD Product Catalog

-

Accessories

Related Articles

Do you want personal advice for your specific control process?

Contact us directly or reach out to your local AMETEK Level Measurement Solutions representative!

FIND MY LOCAL REPRESENTATIVE