L500 Series

Custom multi-level float switches for large tanks

The wider displacement L500 Multi-Level Float Switch is designed to monitor up to six levels on a single device. With only a single entry, the L500 can track changing levels within a large tank, as well as monitor liquid interfaces of dissimilar liquids for oil/water separations, chemical emulsions and condensation levels. Probe lengths are available up to 15′ with numerous combinations of floats, mounts and materials to suit every application. Additional options include a variety of enclosures, as well as integrations with thermostatic switches to provide level and temperature sensing capabilities within one control.

-

Features

-

Wiring options

-

Mounting and materials

-

Float Specifications

-

Downloads

- Modular Design

- Probe Lengths Up to 15′

- Capable of Up to 6 Switch Positions

- 50 VA Switch (Standard)

- Adjustable & Thermostatic Switch Model Options

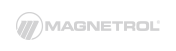

Operation is based upon simple buoyancy, whereby a spring is loaded with weighted displacers, which are heavier than the liquid. Immersion of the displacers in the liquid results in buoyancy force changing to net force acting on the spring. The spring compresses as the buoyancy force increases.

A magnetic sleeve is connected to the spring and operates within a non-magnetic barrier tube. Spring movement causes the magnetic sleeve to move into the field of a pivoted magnet, actuating a switch mechanism located outside the barrier tube. Built-in limit stops prevent over stroking of the spring, under level surge conditions.

A magnetic sleeve is connected to the spring and operates within a non-magnetic barrier tube. Spring movement causes the magnetic sleeve to move into the field of a pivoted magnet, actuating a switch mechanism located outside the barrier tube. Built-in limit stops prevent over stroking of the spring, under level surge conditions.

| 1/2" NPT | BRASS | SPST 20 VA | NO ENCLOSURE |

| 1" NPT | Polypropylene | SPST 50 VA | Polypropylene NEMA 4 |

| 1-1/4" NPT | PVC | SPST 100 VA | Cast Aluminum NEMA 4/7/9 |

| 1-1/2" NPT | 316 Stainless Steel | SPDT 3 VA | Cast Iron NEMA 4/7/9 |

| 2" NPT | Teflon® (PFA) | ||

| 2" #150 ANSI Flange | |||

| 3" #150 ANSI Flange | |||

| 4" #150 ANSI Flange |

| POLYPROPYLENE (HOLLOW) | 1.875" X 1.906" | -40º TO +150º F (-40º TO +65.6º C) | 50 PSIG (3.4 BAR) | 0.48 |

| 316 Stainless Steel | 1.5" x 1.3" | -40º to +300º F (-40º to +148.9º C) | 120 PSIG (8.3 bar) | 0.8 |

| 316 Stainless Steel | 2" Ball | -40º to +300º F (-40º to +148.9º C) | 750 PSIG (51.7 bar) | 0.79 |

| Teflon® (Hollow) | 2.150" x 1.980" | -40º to +300º F (-40º to +148.9º C) | 40 PSIG (2.8 bar) | 0.84 |

| Buna-N | 1.250" x 1.875" | -40º to +180º F (-40º to +82.2º C) | 150 PSIG (10.3 bar) | 0.64 |

| Buna-N | 1.875" x 1.750" | -40º to +180º F (-40º to +82.2º C) | 150 PSIG (10.3 bar) | 0.57 |

| PVC (Hollow) | 1.875" x 1.906" | -40º to +150º F (-40º to +65.6º C) | 50 PSIG (3.4 bar) | 0.69 |

Accessories

Related Articles

Do you want personal advice for your specific control process?

Contact us directly or reach out to your local AMETEK Level Measurement Solutions representative!

FIND MY LOCAL REPRESENTATIVE