- September 28, 2023

Driving Down Fuel Costs With Feedwater Heater Level Control

For most power plants, 70 to 80% of their production costs are fuel expenses. Hence, any improvement in fuel efficiency can have a significant impact on a plant’s profitability. By improving final feedwater heater temperature through better feedwater heater level control, plants can reduce heat rate and realize significant cost savings. For instance, in a 500-megawatt power plant, improving heat rate by 1% could generate $500,000 in annual savings.

Heat rate is a measure of how efficiently a plant uses heat energy. The higher the heat rate, the less efficient the plant. Heat rate has a major impact on a company’s bottom line and its ability to compete in unregulated markets. The benefits of an improved heat rate go well beyond consumption and cost. A plant can see a reduction in emissions by simply reducing the amount of fuel required to generate a given amount of energy. In many cases this can be accomplished in a cost-effective manner by improving feedwater heater level control. Reducing heat rate also increases boiler longevity by eliminating overfiring. And there is significant public relations value when a plant shows itself to be taking all possible steps to minimize its impact on the environment.

Level Control Throughout the Power Cycle

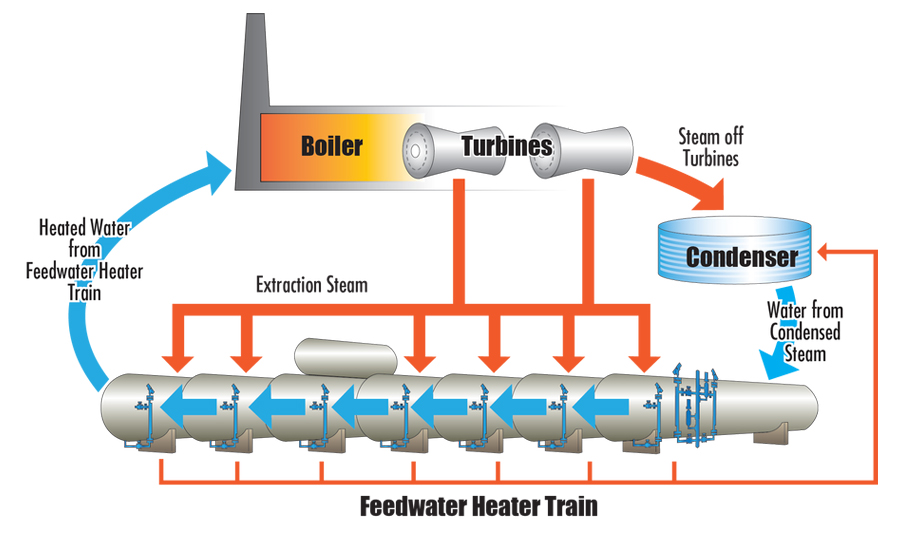

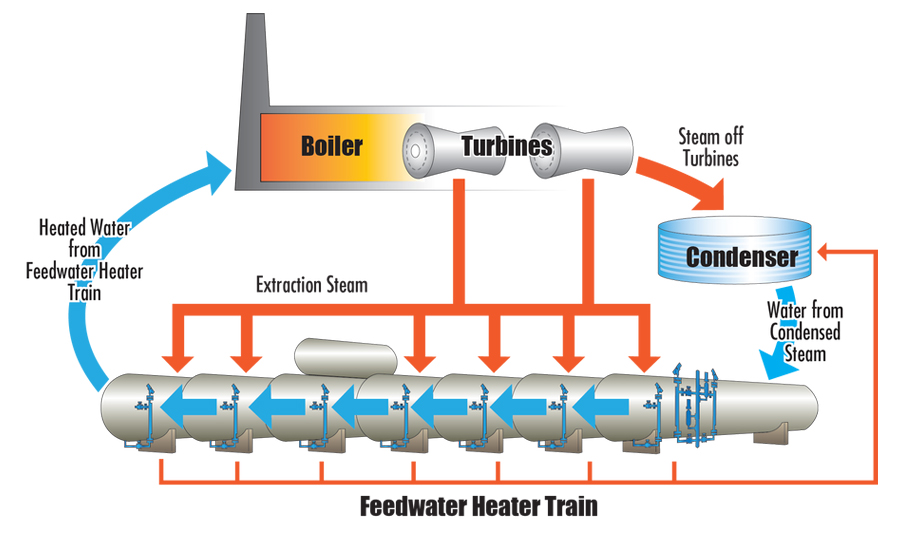

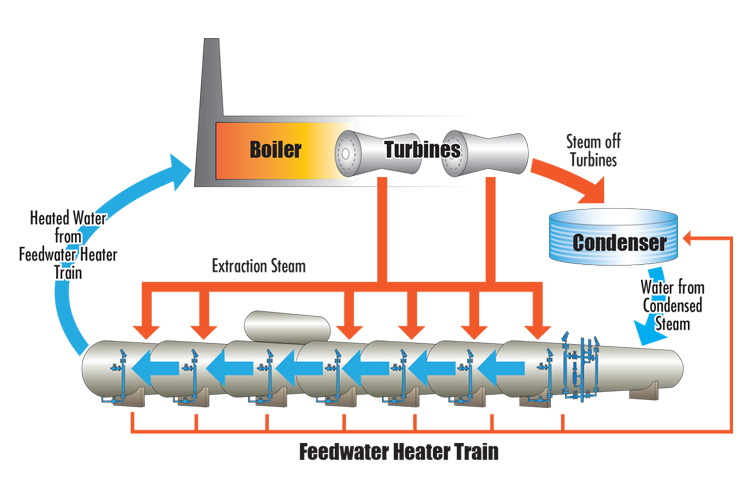

Maintaining accurate, reliable level control throughout the power cycle is critical. The condenser is the beginning of the feedwater heater process, where condensed steam from feedwater heater drains and HP, IP, and LP turbines is routed through successive feedwater heaters. At the same time, extraction steam from turbines reaches the appropriate feedwater heaters and the transfer of energy takes place. Reliable, accurate level control is critical to achieving the final temperatures that this cycle requires.

Feedwater Heater Operation

Feedwater heaters use the heat of condensation to preheat water to the correct temperature for the boiler. During this process, shell and tube heat exchangers allow feedwater to pass through the tube side and extract water from the turbine to the shell side. When controlled properly, feedwater heaters can decrease fuel costs by using extraction steam to preheat water rather than costly hot fuel. Achieving optimum water level in the feedwater heater reduces heat rate and lowers fuel costs. Making an investment in level control can help you achieve optimum heat.

Instrumentation for Feedwater Heater Level Control

The Eclipse® Model 706, a guided wave radar transmitter produced by Magnetrol®, is a smart choice for monitoring feedwater heater level control. The Eclipse 706 guided wave radar (GWR) transmitter can help plant operators optimize the condensing zone, deliver accurate level control, maximize energy transfer, and minimize undue wear and tear.

While older level technologies, such as differential pressure, magnetostrictive, RF capacitance, and torque tubes are often used to measure feedwater heater level, these instruments can cause issues for power plant operators. Older technologies such as these are vulnerable to process conditions, induced instrument errors, shifts in specific gravity and mechanical or electronic drift.

GWR is the truly reliable measurement solution for feedwater heater level control, because it is unaffected by process conditions, requires no calibration or gravity corrections, and has superior signal-to-noise ratio. Using a guided wave radar transmitter like the Eclipse Model 706 can help power plants achieve a reduced heat rate and lower fuel costs.

More Information

Download the Feedwater Heater Level Control brochure to learn more.

Heat rate is a measure of how efficiently a plant uses heat energy. The higher the heat rate, the less efficient the plant. Heat rate has a major impact on a company’s bottom line and its ability to compete in unregulated markets. The benefits of an improved heat rate go well beyond consumption and cost. A plant can see a reduction in emissions by simply reducing the amount of fuel required to generate a given amount of energy. In many cases this can be accomplished in a cost-effective manner by improving feedwater heater level control. Reducing heat rate also increases boiler longevity by eliminating overfiring. And there is significant public relations value when a plant shows itself to be taking all possible steps to minimize its impact on the environment.

Level Control Throughout the Power Cycle

Maintaining accurate, reliable level control throughout the power cycle is critical. The condenser is the beginning of the feedwater heater process, where condensed steam from feedwater heater drains and HP, IP, and LP turbines is routed through successive feedwater heaters. At the same time, extraction steam from turbines reaches the appropriate feedwater heaters and the transfer of energy takes place. Reliable, accurate level control is critical to achieving the final temperatures that this cycle requires.

Feedwater Heater Operation

Feedwater heaters use the heat of condensation to preheat water to the correct temperature for the boiler. During this process, shell and tube heat exchangers allow feedwater to pass through the tube side and extract water from the turbine to the shell side. When controlled properly, feedwater heaters can decrease fuel costs by using extraction steam to preheat water rather than costly hot fuel. Achieving optimum water level in the feedwater heater reduces heat rate and lowers fuel costs. Making an investment in level control can help you achieve optimum heat.

Instrumentation for Feedwater Heater Level Control

The Eclipse® Model 706, a guided wave radar transmitter produced by Magnetrol®, is a smart choice for monitoring feedwater heater level control. The Eclipse 706 guided wave radar (GWR) transmitter can help plant operators optimize the condensing zone, deliver accurate level control, maximize energy transfer, and minimize undue wear and tear.

While older level technologies, such as differential pressure, magnetostrictive, RF capacitance, and torque tubes are often used to measure feedwater heater level, these instruments can cause issues for power plant operators. Older technologies such as these are vulnerable to process conditions, induced instrument errors, shifts in specific gravity and mechanical or electronic drift.

GWR is the truly reliable measurement solution for feedwater heater level control, because it is unaffected by process conditions, requires no calibration or gravity corrections, and has superior signal-to-noise ratio. Using a guided wave radar transmitter like the Eclipse Model 706 can help power plants achieve a reduced heat rate and lower fuel costs.

More Information

Download the Feedwater Heater Level Control brochure to learn more.

Heat Rate and Feedwater Heater Level Control

Download our white paper to minimize controllable losses tied to feedwater heater performance by gaining additional insight into the basic feedwater heater and power cycle operations; associated performance indicators and the positive or negative impact of level control on overall plant efficiency as related to net unit heat rate and cost containment.

Download