Model TK1 liquid level switch

The TK1 liquid level switches are float-actuated devices designed for horizontal mounting in a tank or process vessel through threaded or flanged connections. This low-cost switch is ideal for OEM applications where a single point high or low level alarm is desired

-

Features

-

Applications

-

Operating principle

-

Downloads

- Pressure ratings to 1500 psi (103 bar)

- Process temperature ratings to +300 °F (+150 °C)

- Specific gravity as low as 0.40

- Compact design

- For use on rising or falling level

- Reliable reed switch action

- All stainless steel construction

Options

- 1½ or 2 inch process connections

- Hermetically sealed reed switch with optional four-wire dry contact relay

- 316/316L stainless steel or cast iron/aluminum enclosure material

- Type of contacts: SPST, SPDT or DPDT

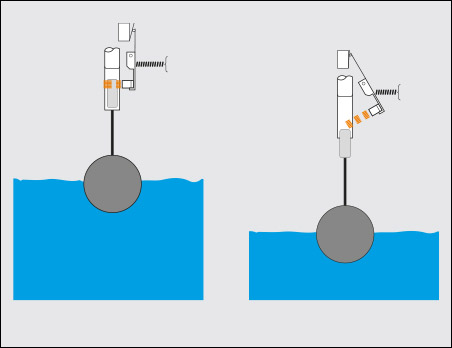

The TK1 achieves switching action through the use of a magnet attached to the float assembly and the magnet’s interaction with a reed switch.

As the liquid level changes, the float and, therefore, the float magnet, moves. The proximity of the float magnet to the reed switch causes the switch to change state, making or breaking an electrical circuit.

Accessories

Related Articles

Do you want personal advice for your specific control process?

Contact us directly or reach out to your local AMETEK Level Measurement Solutions representative!

FIND MY LOCAL REPRESENTATIVE