Tuffy® pneumatic side-mounted float switch

The Pneumatic Tuffy® liquid level switch is a compact pneumatic level switch designed for horizontal mounting in a tank or vessel through threaded or flanged pipe connections.

-

Features

-

Applications

-

Operating principle

-

Downloads

- All 316 SS wetted components

- Process pressures to 1500 psig (103 bar)

- NACE and/or ASME B31.3 construction

- Specific gravity as low as 0.40

- 2-inch NPT mounting

- Process temperatures from -40 to +300 °F (-40 to +150 °C)

Options

- Specific gravity rating

- Carbon steel and stainless steel external mounting cages

- Variety of thread-on flanges

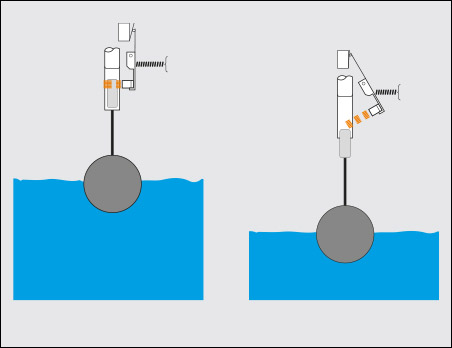

Buoyancy force of process liquid on a float causes the float to move with the liquid's surface. Float movement pivots a magnet into the field of a like-charged switch magnet. As the magnets repel each other, the switch magnet moves, actuating the switch.

-

Instruction Manuals

-

Product Catalogs

-

USA Tuffy Liquid Level Controls With Pneumatic Switch Product Catalog

-

English Tuffy Liquid Level Controls With Pneumatic Switch Product Catalog

-

French Tuffy Liquid Level Controls With Pneumatic Switch Product Catalog

-

German Tuffy Liquid Level Controls With Pneumatic Switch Product Catalog

-

Italian Tuffy Liquid Level Controls With Pneumatic Switch Product Catalog

-

Accessories

Related Articles

Do you want personal advice for your specific control process?

Contact us directly or reach out to your local AMETEK Level Measurement Solutions representative!

FIND MY LOCAL REPRESENTATIVE