Catalytic crackers

The Fluid Catalytic Cracking Unit (FCCU) cracks heavy, low-value feedstocks into high-value, lighter molecular weight hydrocarbons which are blended to finished products. A cracker can produce a wide variety of yield patterns by operating in either Gasoline, Distillate or LPG modes.

Challenge

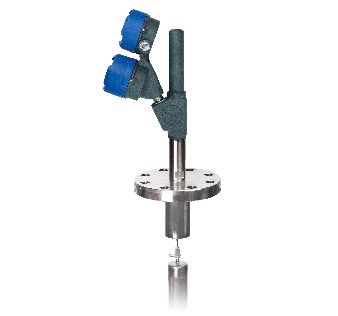

Catalytic crackers utilize a reactor and a catalyst regenerator with connecting risers where the reactions take place. Level controllers are often positioned on the first stage regenerator and at the top of the reactor. Level measurements involve fluidized solids levels at high temperatures. Conventional measurement techniques can be subject to plugging.

Related products

Other applications

Do you want personal advice for your specific control process?

Contact your local AMETEK Level Measurement Solutions representative!

Find my local representative