Biofuel

Biofuel is produced from biomass resources to make liquid fuels like ethanol, methanol, and biodiesel, and gaseous fuels such as hydrogen and methane (see Biogas). Biofuels are primarily used to fuel transportation vehicles, but they can also fuel engines or fuel cells for electricity generation.

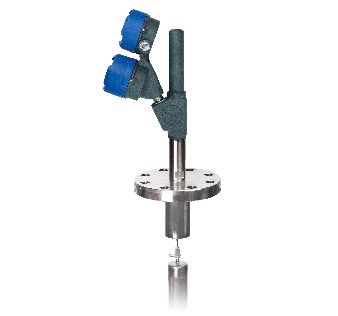

Biofuel level applications

- FERMENTATION: In ethanol production, fermentation provides a series of chemical reactions that convert sugars to ethanol. Ethanol and carbon dioxide are produced as the sugar is consumed by yeast or bacteria. Level control of the fermentation tank must tolerate agitation, aeration, and the presence of froth or foam.

- REACTOR TANK: Biodiesel and cellulosic ethanol production use reactors for chemical addition and mixing. In a Continuous Stirred-Tank Reactor one or more fluid reagents are introduced into a tank reactor equipped with an impeller that stirs the reagents to ensure proper mixing. The reactor tank requires level monitoring and alarms.

- REAGENT TANK: A reagent is a compound that is added to a system in order to bring about a chemical reaction. In biodiesel production, an alkali reagent is used in titration, a test used to determine how much catalyst is needed to achieve a reaction. Reagents are stored in tanks equipped with level controls.

- SUMPS: Liquids are collected in sumps and pits during hydrolyzation, fermentation, distillation and glucose processing of biofuels. As the liquid level rises or falls in a sump, a level switch can actuate or deactuate a pump or activate an overfill alarm.

- LIQUID STORAGE: A wide array of liquids are stored at biofuel plants including water, biodiesel, methanol, ethylene, catalysts, and waste liquids. Level instruments monitor inventory levels and protect against overfills and underfills that cavitate pumps.

Related products

Other applications

Do you want personal advice for your specific control process?

Contact your local AMETEK Level Measurement Solutions representative!

Find my local representative