Float Level Switches

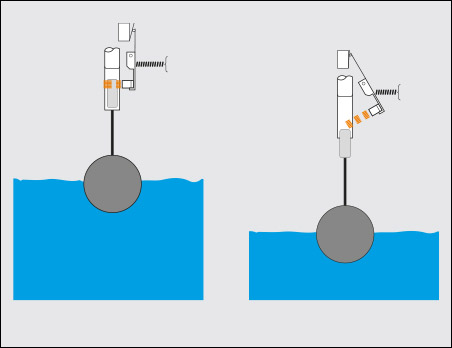

How Float Level Switches Work

Float level switches—sometimes called float level controls—rely on the classic buoyancy principle: the upward force on an object equals the weight of the liquid it displaces. In practice, a precision-balanced stainless-steel or alloy float rides on the liquid surface and moves exactly as the liquid level rises or falls.

Inside every AMETEK LMS float switch, that motion pulls a magnetic sleeve through a non-magnetic barrier tube and into (or out of) the field of a switch-actuating magnet, producing a clean, snap-action change of state.

The result is a rugged, drift-free signal for high-level alarms, low-level cut-outs, pump control, or interface detection—even in demanding services up to 1000 °F (538 °C), 3750 psig (258 bar), and specific gravities down to 0.32

Why Choose AMETEK LMS for Float Level Switches

- Engineer-to-Engineer Collaboration - Our level-measurement specialists review your P&ID, process fluid data, and environmental conditions to specify the exact float geometry, stem length, mounting style, and switch type your application needs - no over-or under-engineering.

- Application-Proven Reliability – Field data show AMETEK LMS float switches exceeding 10-year mean-time-between-failure (MTBF) in high-cycle refinery and power-plant service. Fewer interventions mean lower total cost of ownership.

- Built for Harsh Service – Proprietary welding, full-penetration radiography, and 100 % helium leak testing ensure each switch survives extreme temperature, pressure, and corrosion without recalibration.

- Lifecycle Support – From start-up assistance and spare-parts programs to on-site health checks, our global service team keeps your measurement loop running.

- Industry Compliance – FM, CSA, ATEX/IECEx, PED, CRN, and SIL options help you meet safety-integrity and regional code requirements without extra paperwork.

Typical Float Level Configurations

| Configuration | Typical Mounting | Best-Fit Use Cases | Highlights |

|

Top-Mounted Float Level Switch |

Threaded or flanged tank roof |

Boilers, scrubbers, condensate receivers |

Up to 20 ft stems; single, dual, or triple switch stacks |

|

Side-Mounted Float Level Switch |

Horizontal nozzle, ANSI or DIN |

Skids, OEM packages, small reservoirs |

Compact profile, easy retrofits |

|

External Cage Float Switch |

Welded to a slip-on or socket-weld chamber |

High-pressure separators, steam drums |

Isolates process from instrument, simplifies maintenance |

|

Interface Float Switch |

Float engineered for immiscible liquids |

Separators, desalters, sumps |

Detects interface between oil/water, acid/caustic, etc. |

Ready to specify a float level switch that simply works - day in, day out? Contact our team and get a tailored quotation.

Discover our Float Level Switches products

Do you want personal advice for your specific control process?

Contact your local AMETEK Level Measurement Solutions representative!

or contact us with any questions.

Find my local representative