Models T20 & T21 top-mounting single-stage and dual-stage float switches

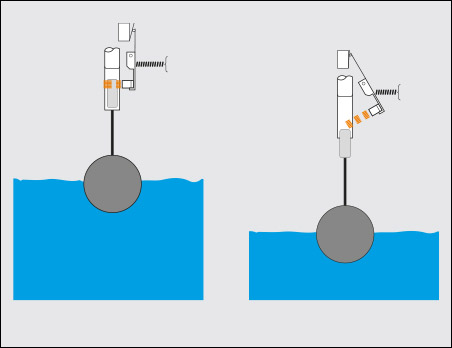

Single Stage Switch

T20 units are simple, reliable float switches, designed for top mounting into tanks or vessels. T20 units utilize a single switch mechanism and float. It can be used for virtually any type of open or closed process or storage vessel, with either threaded or flanged type mounting, and actuating depths of up to 48 inches (1219 mm).

Dual Stage Switch

T21 units combine the functions of two separate narrow differential level controls in a single, compact, easy-to-install instrument. Two independent switch mechanisms are employed to provide two actuating levels at least 8” apart, at actuating depths of up to 48 inches (1219 mm), for applications such as high and low level alarm operation. Model T21 tandem float switches are available with optional cages to help stabilize the floats under turbulent conditions.

-

Features

-

Applications

-

Operating principle

-

Approvals

-

Downloads

- Float diameters of 3" × 5", 4" and 4½" available

- Tank connections available in 1" NPT, cast iron, forged, or stainless steel flanges

- Choice of switch mechanism: ◦ Dry contact ◦ Hermetically sealed ◦ Pneumatic

- Choice of switch enclosure: ◦ NEMA 1 carbon steel for pneumatics

◦ TYPE 4X/7/9 Class I, Div. 1, Groups C & D, polymer coated aluminum

◦ TYPE 4X/7/9 Class I, Div. 1, Group B, polymer coated aluminum

Options

- NACE

- ATEX approved housing

- Housing heater

- Float guide cage

- Tropicalized switch mechanism

- Special flange face finishes

- Submersible housing

- Elevated temperature

| ATEX | Ex d, Ex ia |

|---|---|

| CCOE | Ex d |

| CSA | XP |

| FM | XP |

| EAC (GOST) |

Ex d, Ex ia |

| IEC | Ex d, Ex ia |

| Inmetro | Ex d |

| Korea |

Ex d |

| NEPSI |

Ex d |

| SIL |

SIL 2 (1oo1) |

Other approvals are available. Consult factory for more details.

-

Approvals and certificates

-

Instruction Manuals

-

Product Catalogs

Accessories

Related Articles

Do you want personal advice for your specific control process?

Contact us directly or reach out to your local AMETEK Level Measurement Solutions representative!

FIND MY LOCAL REPRESENTATIVE