Horizontal separators

CHALLENGES

Lack of control of the emulsion layer in the separator means fluctuations in lift costs per BOE:

- Not accomplishing primary goal: removing water from oil

- Reduced separator efficiency and equipment uptime

- Increased cost of demulsifiers to break down rag layer

- Transmitter may not be specified for interface versus total level

- Potential buildup on existing contacting devices

- Direct impact to the overall dehydration process, liquid storage, and water treatment systems

SOLUTION

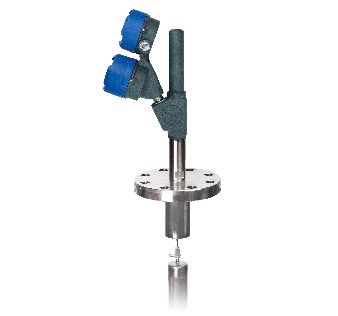

Magnetrol® level devices optimize separator performance by keeping tighter control of the emulsion layer

- Recommend device close to the weir to maximize retention time which assists oil-water separation

- Thinner rag layer optimizes level device performance

- Single transmitter design for total level and interface

- Enhanced diagnostics for buildup detection (paraffinsor asphaltenes)

- Low power to cycle up and down quickly (O&G E&P)

- Breadth of transmitters by SG/API gravity

RESULTS

Better level measurement and tighter control of the emulsion layer

- Separator optimization due to accurate representation of water in oil (top of emulsion)

- Reduced cost for demulsifiers (cost is an estimated $1.5–$2K USD per ton)

- Increased downstream equipment uptime due to improved oil-water separation

- Reduced maintenance due to reliable signal and enhanced diagnostics

- Simplified commissioning and training with communication through desired protocols

Related products

Other applications

Do you want personal advice for your specific control process?

Contact your local AMETEK Level Measurement Solutions representative!

Find my local representative