Crude dehydration

Not all water is removed from crude oil during the first stage of gravity separation. Separated crude may contain up to 15% water which exists in an emulsified form that is difficult for a separator to remove. The oil and water emulsion must be broken down so that the water can be removed before the crude is shipped. Deemulsification processes are accomplished using chemical agents and heat.

Challenge

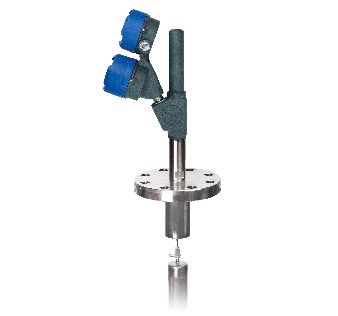

Level control is found on two-phase and three-phase water knock out drums, heater treaters and chemelectric dehydrators. Interface measurement is critical in dehydration as it keeps the water-emulsified oil from flowing over the separator weir.

Related products

Other applications

Do you want personal advice for your specific control process?

Contact your local AMETEK Level Measurement Solutions representative!

Find my local representative