Condensate receiver tanks

Steam generated in the recovery boiler is used to run many parts of a mill. Liquor concentration and paper drying are the largest steam users, followed by digestion, bleaching, and chip steaming. (Steam also drives a turbine cogeneration system if a mill is so equipped). A steam condensate system in the paper machine’s dryer section collects water for reuse in the mill.

Challenge

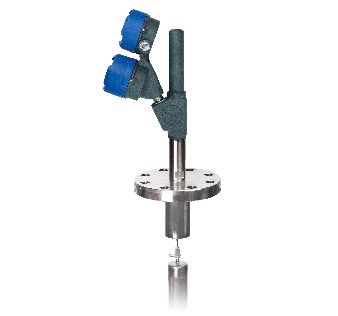

Steam condensate from the dryer drums enters up to half a dozen receiver tanks of the condensate return system. Level controls in these tanks ensure that water either is returned to the mill for reuse, diverted to storage, or discharged to the sewer. When the control senses the upper level in the tank it will actuate a dump valve to remove the accumulated condensate.

Related products

Other applications

Do you want personal advice for your specific control process?

Contact your local AMETEK Level Measurement Solutions representative!

Find my local representative