Compressor Scrubber

Natural gas can travel through thousands of miles of pipeline. Compressors placed at key intervals keep the natural gas moving evenly and reliably. A typical compressor station consists of an inlet scrubber to collect liquids and slugs that may have formed in the gas pipeline. The scrubber consists of a primary section where liquids and solid parts are separated from the gas stream and a secondary section where oil mist is removed.

Challenges

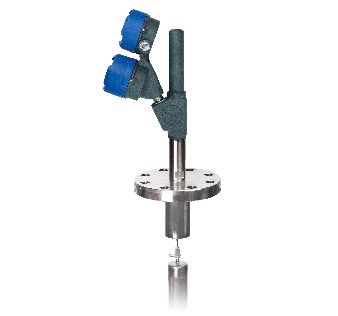

The liquids collected from the suction scrubber are typically routed by way of scrubber level control valves to a low pressure (LP) tank. The vapors produced from the flashing liquids are vented to the atmosphere or to a flare. The low pressure condensate is periodically trucked out. Scrubbers are often equipped with high and low level alarms.

Related products

Other applications

-

Chemical injection skids

Chemical agents employed in field processing include drilling fluid additives, methanol injection for reservoir stimulation, glycol injection for hydrate inhibition, produced water treatment chemicals, foam and corrosion inhibitors, de-emulsifiers, desalting chemicals and drag reduction agents (DRAs).

Do you want personal advice for your specific control process?

Contact your local AMETEK Level Measurement Solutions representative!

Find my local representative