Sulfur Recovery

A sulfur recovery unit converts the hydrogen sulfide in the acid gas into elemental sulfur. Of the processes available for these conversions, the Claus process is by far the most well-known for recovering elemental sulfur, whereas the conventional Contact Process and the WSA

Process are the most used technologies for recovering sulfuric acid. The residual gas from the Claus process is commonly called tail gas. Tail gas is subsequently processed in a gas treating unit.

Challenges

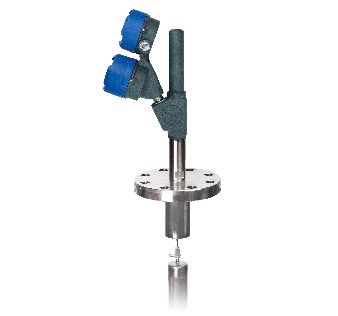

The sulfur condenser vessel is equipped with a disengagement section on the outlet end in order to allow for efficient separation of the liquid sulfur from the process gas. A collection vessel equipped with continuous level control is used to store and remove the sulfur product from the process.

Related products

Other applications

-

Chemical injection skids

Chemical agents employed in field processing include drilling fluid additives, methanol injection for reservoir stimulation, glycol injection for hydrate inhibition, produced water treatment chemicals, foam and corrosion inhibitors, de-emulsifiers, desalting chemicals and drag reduction agents (DRAs).

Do you want personal advice for your specific control process?

Contact your local AMETEK Level Measurement Solutions representative!

Find my local representative