Vapor recovery unit

If allowed to escape into the atmosphere, hydrocarbon vapors diminish income through loss of hydrocarbon volume and create fire hazards and pollution problems. A Vapor Recovery Unit (VRU) collects vapors from storage and loading facilities, reliquefies the vapors and returns the liquid hydrocarbons back to storage. Methods to recover vapors include absorption, condensation, adsorption and simple cooling.

Challenge

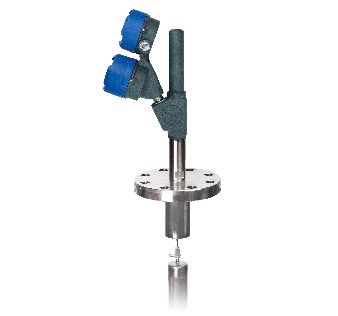

A VRU is a simple, economical process unit that provides EPA compliance and improves operating economies by capturing up to 95% of fugitive emissions. Critical to the VRU is the flash drum where vapors are reliquefied. Liquid level control of the flash drum is essential.

Related products

Other applications

-

Chemical injection skids

Chemical agents employed in field processing include drilling fluid additives, methanol injection for reservoir stimulation, glycol injection for hydrate inhibition, produced water treatment chemicals, foam and corrosion inhibitors, de-emulsifiers, desalting chemicals and drag reduction agents (DRAs).

Do you want personal advice for your specific control process?

Contact your local AMETEK Level Measurement Solutions representative!

Find my local representative