Flare Knock-out Drum

Liquid in the vent stream can extinguish the flame or cause irregular combustion and smoking. In addition, flaring liquids can generate a spray of burning chemicals— a “rain of fire”—that create a severe safety hazard. A knockout drum collects these liquids prior to entering the flare system. A level gauge and drain connections are built into the knockout drum.

Challenges

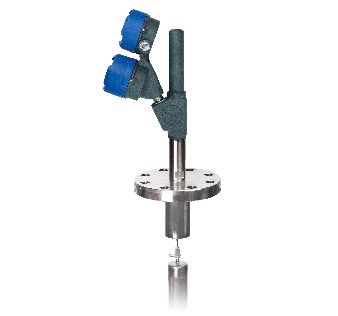

When a large liquid storage vessel is required and the vapor flow is high, a horizontal drum is usually more economical. Vertical separators are used when there is small liquid load, limited plot space, or where ease of level control is desired. Knockout drums are equipped with instrumentation to monitor liquid level with pump out or drain facilities. High and low level alarms are frequently installed in knockout drums.

Related products

Other applications

-

Chemical injection skids

Chemical agents employed in field processing include drilling fluid additives, methanol injection for reservoir stimulation, glycol injection for hydrate inhibition, produced water treatment chemicals, foam and corrosion inhibitors, de-emulsifiers, desalting chemicals and drag reduction agents (DRAs).

Do you want personal advice for your specific control process?

Contact your local AMETEK Level Measurement Solutions representative!

Find my local representative