Protecting Against Damage to Progressing Cavity Pumps

Progressing cavity pumps are used in the important process of conveying thick slurries and other process fluids with high solids content. They rely on a constant supply of fluid for lubrication. If the pump runs dry, the internal components and motor can be damaged, requiring expensive repairs and costly down time.

The solution to this costly problem is to monitor the pump suction and shut it down before it runs dry. Several creative approaches to protecting against running dry have been used, including measuring current draw of the motor or measuring torque on the drive shaft.

Both these methods react to a change due to loss of material in the pump. However, shut down occurs after the pump has started running dry, which is often too late to prevent damage. At a minimum, it will decrease pump life. Also, since current and torque are not linear functions of friction, it is difficult to ensure a pump shut down prior to damage.

Monitoring the process material being pumped is a much better approach and can shut down the pump when the upstream leg becomes empty. This ensures that the pump will not be run in a dry condition. The most common methods for measuring the absence of fluid are pressure, flow, conductance, or RF admittance switches.

Considering the cost of an installed pump, rebuilding a pump and the cost per hour of downtime, a reliable monitoring switch is obviously a wise investment. It is an investment that pays for itself many times over by extending pump life and preventing costly damage.

AMETEK Drexelbrook, an acknowledged leader in level measurement, provides the ClearLine™ Fluid Detector as part of its level and analytical measurement product line. The Clear Line is designed specifically for pipe and tank applications in the hydrocarbon, pharmaceutical, chemical and food processing industries, in which it monitors the presence or absence of fluid in a pipe to provide complete assurance that the tank is empty.

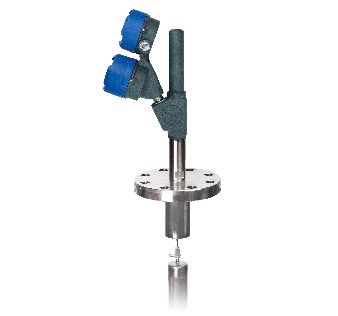

The ClearLine detector mounts directly into existing pipelines between two standard 150-lb, flat-faced flanges. Without interfering with product flow as some other applications can, it uses RF admittance technology to detect when material is present or absent from a pipe. This is especially important for the users of expensive pumps who want to prevent damage or burn out from a pump running empty.

The sanitary, crevice-free design of the ClearLine detector means no cracks, and the ultrasmooth surface is ideal for shear-sensitive products. Routine maintenance is not required, making it a practical application for any progressing cavity pump.

Among other solutions to dry running pumps are point level switch technologies. One common type of which are pressure switches. Pressure switches measure the increase or decrease in head pressure on a diaphragm. A reduction of head indicates an emptying or empty pipe, and signals the pump to shut down.

Pressure switches are notorious for failing due to material plugging the diaphragm. A plugged diaphragm will not respond to changes in the pipe emptying, resulting in damage to the pump. Pressure switches, therefore are a much less reliable choice for pump protection than the ClearLine fluid detector, because they are more prone to failure.

Flow switches are another commonly used technology to combat dry running. There are several types of flow switches available, including mechanical and thermal dispersion switches.

Both technologies require a sensor inserted into the flow stream, which contributes to pipeline plugging, unlike the ClearLine fluid detector which lies flush with the pipe walls.

Mechanical flow switches utilize a paddle or target on the end of a pivot arm. Material flow deflects the target indicating flow. A major drawback of these devices is that they are mechanical. The pivot and spring assemblies are susceptible to wear and corrosion. Solids in the process material being measured also can damage the assembly.

Thermal dispersion switches are made up of two thermal wells inserted into the process material. The first thermal well contains a reference sensor that monitors the process temperature. The second thermal well includes a heater that is the active sensor. As material flows past the assembly, heat is dispersed from the active sensor, reducing the differential between the active and reference sensors and indicating process flow.

Thermal dispersion sensors, being an insertion type technology, are subject to wear and impact damage from solids in the process material. Thermal dispersion sensors also are relatively slow in response time, allowing the pump to run dry prior to shutting down, resulting in reduced pump life.

Another preventative measure, conductivity switches are sometimes used in pump protection. They can be a poor choice for a number or reasons. Conductivity switches are notorious for material bridging between the active electrode and ground, resulting in a false indication of level. This allows the pump to run dry. The process material may leave a hard, insulating coating on the electrode as it dries, or an oil coating, insulating the conductivity sensor. The insulation can prevent the switch from passing current, which means it doesn’t “see” material shutting the pump down when there is plenty of lubricant available.

The Drexelbrook® ClearLine™ switch is the most reliable choice for pump protection. It is a non-intrusive sensor and does not contribute to pipe blockages. The sensing element has no moving parts to be damaged; and the reliable RF driven-shield circuitry ignores even heavy coatings on the sensing element eliminating false indication of process material.

Thousands of units have been installed with many years of proven field results. The ClearLine requires no routine maintenance. Sensors are available to fit most pipes from 2 inch up to 6 inches in diameter.

Each ClearLine switch is factory calibrated to provide reliable, repeatable performance regardless of changes in process fluids and coatings, or variations in temperature or density. Drexelbrook’s proprietary Cote-Shield™ circuitry ensures dependable detection regardless of conductive coatings or product build up on the sensor.

The ClearLine works without recalibration on processes in which fluids can vary from organics to caustics. It also can be used for interface detection to accurately determine when a material changes from one phase to another. This is especially useful in processes involving material separation.

Related products

Other applications

-

Splitter box level

Wastewater treatment facilities with a large number of primary clarifiers often employ a concrete tank with chambers and gates known as a splitter box, or distribution box, to split the influent flow into multiple streams that are routed into the bank of clarifiers. A similar device may also be used to split mixed liquor flows between secondary clarifiers.

Do you want personal advice for your specific control process?

Contact your local AMETEK Level Measurement Solutions representative!

Find my local representative