Continuous Level Measurement of Cement

The Application

Continuous measurement of cement powder in storage silos.

The Problem

Cement silos are a difficult level measurement. The height of the silos, often 100 or more feet, precludes many technologies. The dusty, dirty environment during filling makes ultrasonic measurement unreliable and mechanical devices, such as plumb bobs, maintenance intensive. In many cases, the silos are still manually sounded. An accurate measurement is needed to ensure that enough product is available for production or that there is enough room in the silo to accept an incoming delivery.

The Solution

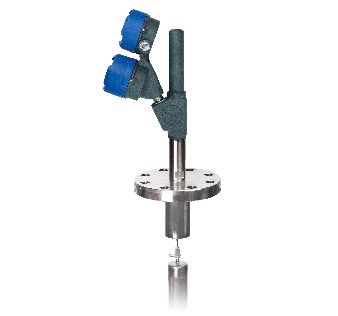

Drexelbrook installed a DR7000 continuous level radar. The Drexelbrook DR7000 provides continuous level measurement regardless of dust, moisture content, or angle of repose of the granular product even during filling! The system eliminates the need for costly, and potentially unsafe, manual readings – especially in inclement weather conditions such as ice, rain, high winds, or snow.

Benefits

· Saves money, automated measurement.

· Process and inventory management are more efficient.

· No routine maintenance required.

· No moving parts to wear out or hang up.

· Safety – no more climbing silos for manual sounding under adverse weather conditions

*Consult factory for higher temperature or pressure.

Related products

Other applications

Do you want personal advice for your specific control process?

Contact your local AMETEK Level Measurement Solutions representative!

Find my local representative