Grain and Feed Silo Level Measurement

Inventory control level measurement on raw feed silos allow material management automation.

The Problem

• Ultrasonic level measurement technologies do not provide the reliability or accuracy that is required for material management in grain and feed silos.

• Radar systems are unable to “see” reflections from most grains and feed stocks. Reliability and accuracy issues are common.

• RF Capacitance technologies do not provide the needed accuracy and require re-calibration with raw material variations.

• Mechanical technologies that use moving parts such as automatic plumb bobs require costly on-going maintenance.

• Manual readings do not provide the repeatability or the consistency that is required to automate material management.

The solution

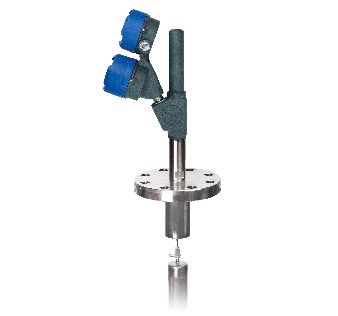

• Drexelbrook DR7100 Series Guided Wave TDR level systems provide accurate level readings on all grain and feed silo level applications to 100 ft and greater.

• Reliable and Repeatable measurement accuracy within 1” of actual level with 0.04” resolution.

• Plug and Play Start-up, No calibration required.

• Easy configuration for 0% & 100% - just set it and forget it.

• No Maintenance, No moving parts, nothing to wear out, accuracy and performance unaffected by dust coatings.

Other Solutions

• Grain silos

• Feed Hoppers

• Caustic storage

• Rotating Filler lines

• Raw material storage

• Dryers

• Blenders

• Sanitary systems

• Dust collectors

• Solvent storage

• Oil storage

• Cyclones

Typical Uses

• Continuous Level Control

• Point Level Control

• Waste Management

• Inventory Management

• Overfill Protection

• Regulatory Compliance

Request more information to see how we can help you with a level measurement solution that suits your need.

Related products

Other applications

Do you want personal advice for your specific control process?

Contact your local AMETEK Level Measurement Solutions representative!

Find my local representative