Point Level Measurement in Granular Storage Silos

Granular storage silos and bins are common in many industries such as Agriculture, Food products, Aggregates, and Mining.

Making point level measurement in a granular material silo would appear to be fairly straightforward but this measurement does offer several challenges.

Storage silos can often be over 50 feet tall. The weight of a granular material in these silos alone will tax the mechanical limits of most technologies. This, along with the dirty, dusty nature of the environment makes mechanical level devices unreliable.

Most installations will require a high level switch connected to a visual or audible alarm to indicate a stop fill point to prevent overfilling the silo. The silo will also have a low level switch to notify the operator when the silo is almost empty. The low level measurement provides an indication to the operator to reorder/refill material. Many facilities will also want a median level switch to indicate when material is starting to run low.

Level Measurement Technologies

The following is an assessment of the four most common point level technologies used for granular measurement.

Paddle Wheels

Paddle wheels, a mechanical device, have often been used as a point level switch for granular measurement. Even with the maintenance issues associated with

mechanical devices, paddle wheels are one of the common technologies selected due to customer’s preference for no-calibration products.

Although relatively low priced with an initial purchase price of $200 - $300 US, paddle wheels require extensive maintenance due to mechanical wear motor fatigue. A paddle wheel motor will fail often, sometimes in as little as 6 months from installation.

Replacement motors cost approximately $100 and up. This, along with the cost of installing the new motor and downtime will have a cost of ownership of many thousands of dollars over a ten-year period. Recent Auto-Calibration developments in other technologies such as RF Admittance make high maintenance paddle wheels an inappropriate selection for measuring granular materials.

* High Maintenance

• Frequent downtime

• High cost of ownership

Tuning Forks and Vibrating Rods

Tuning forks and vibrating rods are often used for granular point level measurement. As with paddle wheels, vibration type sensors do not require calibration. Although vibrating sensors require less maintenance then paddle wheels, they are susceptible to damage caused by abrasion or weight loading. In light materials, vibration devices can “Rat Hole”. Rat holing refers to the vibrating rod or fork “tunneling” out the granular material causing them to no longer “see” the material being measured.

Tuning forks and vibrating rods have been found not to be suitable for silos that have vibrators used to help move material.

• Easily damaged

• Subject to “rat holing”

• Can’t be used on vibrating bins

Capacitance

Capacitance switches have been used for point level granular measurement but do require a one-time calibration at start up. Capacitance switches operate by measuring changes in capacitance between two plates (The sensing element and ground) caused by increases or decreases in the material level. Capacitance switches can give false level indications due to material build up on the sensor. Another phenomenon that can affect capacitance switches is due to drift in measured capacitance caused by temperature changes.

Capacitance switches are calibrated to a balance point between the capacitance generated by the sensor in the vessel and the tuning potentiometer. As temperature drops the capacitance on the sensor side of the circuit increases causing the switch to give a false alarm indication. Both of these problems are eliminated by using RF Admittance switches (see below).

• False trips due to coatings

• False trips due to temperature changes

• Requires calibration

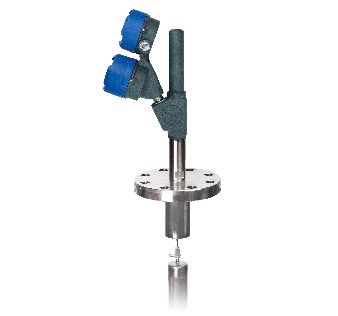

RF Admittance

Drexelbrook RF Admittance level switches such as ThePoint and the Intellipoint are true nocalibration products. Simply connect power and these products calibrate themselves. The sensors are robust, industrial designed for measuring anything from light plastic powders to heavy rock and coal. There are no moving parts to wear, burn out, or jam. RF Admittance level switches are similar to capacitance technology but have driven shield circuitry, which eliminates errors and false trips due to build up on the sensor or drift caused by changes in temperature. Electronic units can be integrally or remotely mounted as preferred by the customer or, as required by the environment of the installation.

RF Admittance level switches are, without doubt, the best solution to granular point level measurement in silos and bins.

• Low cost of ownership (Mean Time To Failure for the Intellipoint is 110 years*)

• No Calibration

• Robust, industrial sensors

• Proven Technology

• Integral or Remote mounting

• No Maintenance

*Source - Exida.com testing

Related products

Other applications

Do you want personal advice for your specific control process?

Contact your local AMETEK Level Measurement Solutions representative!

Find my local representative