Use of RF and TDR for Interface Measurement

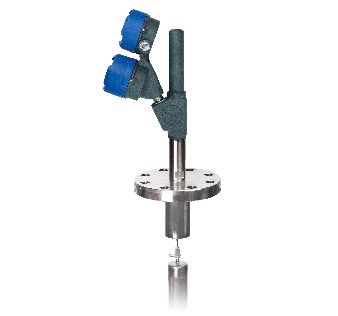

These are two technologies, which have excellent performance in the correct interface applications. In general, the TDR (DR7100 guided wave radar) is the choice for storage tanks, while the RF (Universal IV series) is the most reliable for processing tanks, especially ThermoElectric separators. Both are “process contact” types with probes which must extend over the entire range to be measured.

The difference is determined by whether a vessel is semi static or dynamic. In the first case, the tank is characterized by long settling times and a very sharp, well-defined transition from hydrocarbon to water. In the second case, high thruput, finite emulsion layer, and several strata with various percentages of the two components characterize the separator.

The main advantages of the DR7100 guided wave radar is its ability to make extremely accurate measurements to the point where its wave is reflected, and the fact that it can handle two reflections with one instrument. This allows it to accurately measure the top surface of the hydrocarbon, as well as a water interface in storage tanks. The reflections are caused by a sharp change in dielectric constant (from 1 to 2.5 at the top, and from 2.5 to infinity at the conducting phase).

In a separator, these advantages are both usually negated, because there is no need for a top measurement when the hydrocarbon is on overflow, and the second transition is not sharp and clean. Since there are so many strata in the upper phase of the separator the second reflection will often come from a smaller dielectric discontinuity (such as from 4 to 15), above the actual electrical interface. These strata are not stable, and at another time the same wave could make the full trip to the electrical interface. A third condition occurs when the strata are ill defined and “ramp up” the dielectric constant gradually, producing a very weak reflection from the electrical interface.

The main advantage of the Universal IV series is that it tracks the electrical interface very reliably, and is unable to sense any other point. This makes it superior in separators, where insulating strata occur, but are highly variable. It ignores anything that is insulating, and responds to the number of feet of conducting liquid that contact it.

In storage tanks the tracking of the electrical interface is also desirable, but it cannot track the top of the organic layer with the same instrument. It is often used to sense the water level with radar or hydrostatic gaging systems that have no interface capability of their own. Even using a second Universal IV for the top level is not often implemented, because the accuracy on insulating materials is on the order of 2%.

In summery, the RF instrument is most desirable in separators and other process tanks, while the TDR is clearly superior in storage tank service.

Request more information to see how we can help you with a level measurement solution that suits your need.

Related products

Other applications

Do you want personal advice for your specific control process?

Contact your local AMETEK Level Measurement Solutions representative!

Find my local representative