Liquid Interface Measurement

The Problems

Many techniques and technologies have been tried with varying degrees of success when attempting to accurately and repeatedly control interface measurements. Density based measurements (differential pressure and displacer) are plagued by temperature variations and process variances in specific gravity

to make accuracy or repeatability a guarantee.

Visual and optical techniques are difficult at best and do not provide assurance that the aqueous phase is not entrained or emulsified in the insulating hydrocarbon phase.

The Solution

Simply put, RF Admittance has a unique inherent ability to separate the electrical (Radio Frequency) current flow between a conductive and non-conductive liquid. In fact, this is the only point that RF Admittance is capable of measuring in a liquid/liquid interface.

Seen by the RF transmitter as a capacitance value generated by the RF sensor, the highly conductive aqueous liquid phase produces a very large amount of capacitance in comparison to the small amount of capacitance produced by the low dielectric constant of the insulating (hydrocarbon) liquid phase.

The value of RF Admittance becomes apparent in the area that lies between the aqueous and insulating phase known as the “rag” layer or emulsion phase. This layer can be significant and is made up of parts of both the hydrocarbon-insulating phase as well as parts of the conductive aqueous phase. The inherent ability of RF Admittance to accurately track the electrical changeover point between continuous conductive to continuous insulating electrical characteristics means a more reliable and repeatable indication and control in interface measurements.

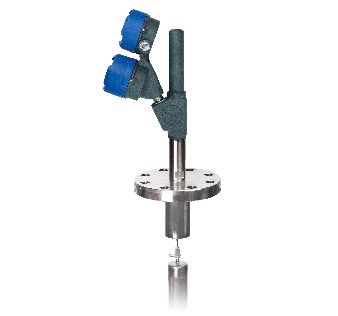

Drexelbrook offers several system designs for both continuous level and point level indication and control of interface measurements, with sensor designs to handle the higher temperatures and pressures and rugged demands that the measurement demands. Systems are available for measurement ranges from less than 12 inches to over 100 feet with a wide range of process connections for both vessel and Displacer chamber retrofit use.

Other Interface Applications

RF Admittance technology can be applied to any liquid / liquid interface that consists of an electrically non-conductive phase over (or under) an electrically conductive phase such as Oil / Water, Solvent / Water, or Oil / Acid, or Solvent / Acid.

In a typical liquid / liquid Interface application, RF Admittance has the ability to define an electrically conductive phase to be any liquid that has conductivity greater than 100 micro-siemens.

In Conclusion

RF Admittance technology has the inherent capability to provide accurate and repeatable performance in liquid / liquid interface applications, more so than any other process measurement technology. RF Admittance relies solely on electrical characteristics of the process material and remains unaffected by changes in temperature, pressure, density, and variations in specific gravity.

Related products

Other applications

Do you want personal advice for your specific control process?

Contact your local AMETEK Level Measurement Solutions representative!

Find my local representative